The reason for uneven cutting of multiple saws

Multi blade saw is a common wood processing tool used for cutting and sawing various types of wood. However, during use, it was found that the surface cut by the saw was not smooth. What is the reason for this? Here are some possible reasons that may cause uneven sawing:

Tool wear or damage: If the saw blade is already worn or damaged, a perfect sawing surface cannot be obtained. Therefore, regular inspection and replacement of cutting tools are very important.

Thickness variation of logs: Some logs may have slight bending or deformation before cutting, which can cause unevenness during sawing.

Improper lathe adjustment: The accuracy of the lathe has a significant impact on the quality of sawing. If not adjusted correctly, it can lead to uneven sawing surfaces.

Using the wrong saw teeth: If the saw teeth used are not suitable for the material to be cut, it will also cause the saw surface to be uneven.

Improper control of sawing speed: Sawing speed that is too fast or too slow can affect the quality of the sawing surface. So, when performing sawing operations, it is necessary to adjust the sawing speed according to the actual situation.

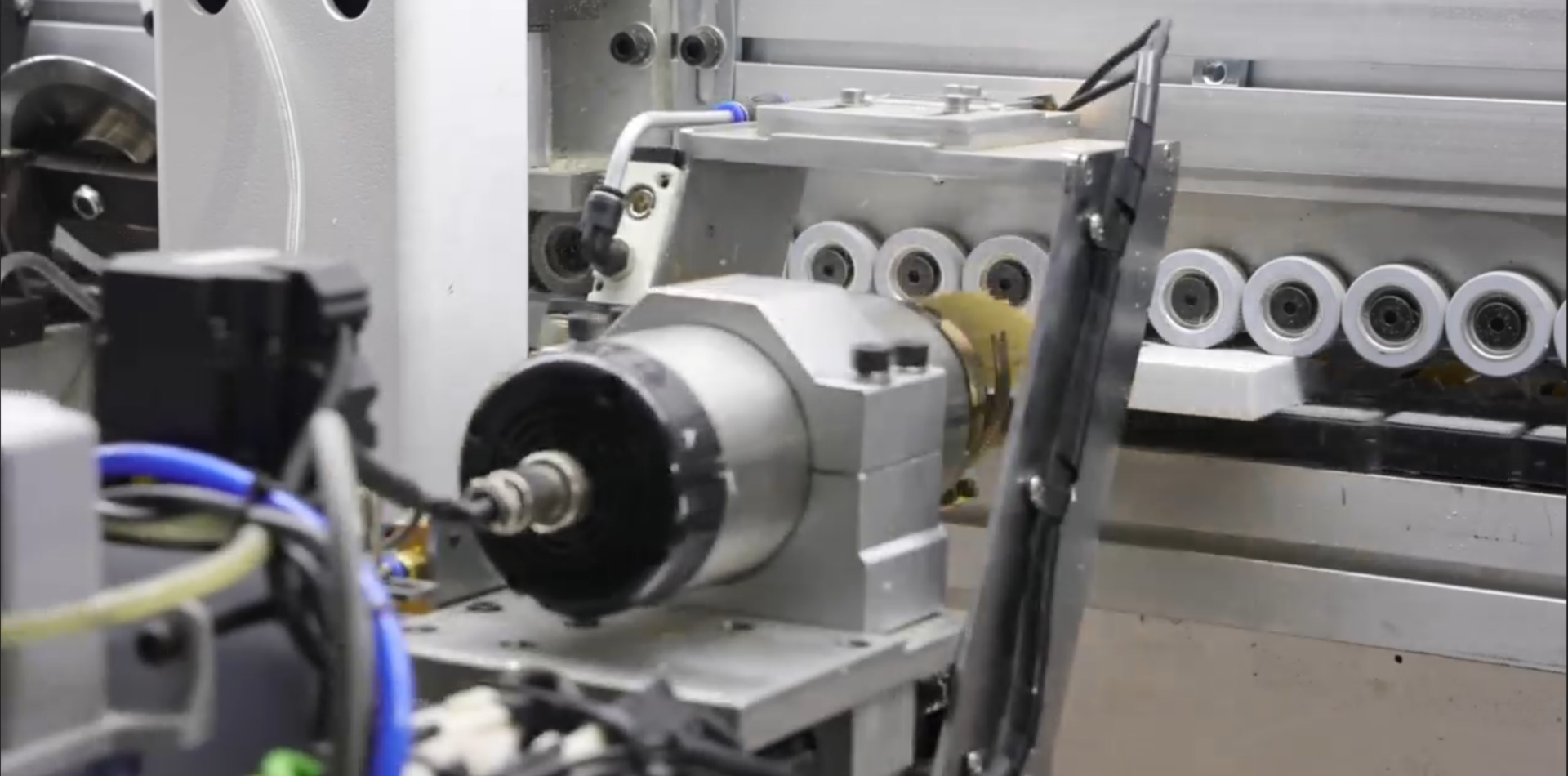

Uneven grinding of the grinding wheel: The grinding effect of the grinding wheel can also affect the flatness of the sawing surface. Therefore, regular inspection and cleaning of the grinding wheel is also necessary.

In general, the main reasons for uneven sawing may be due to various factors, such as tool wear, changes in the thickness of logs, precision adjustment of lathes, improper selection of serrations, and improper control of sawing speed. Therefore, in the process of using a multi blade saw, it is necessary to observe carefully, identify problems in a timely manner, and take corresponding measures to ensure the quality of sawing.

中文

中文  España

España  Français

Français  Русский

Русский  Português

Português  Tiếng Việt

Tiếng Việt  แบบไทย

แบบไทย